USA-based aftermarket winglet manufacturer Tamarack Aerospace is repurposing 3D printers normally used to produce aircraft parts to make masks for a local hospital that faces shortages during the Covid-19 pandemic.

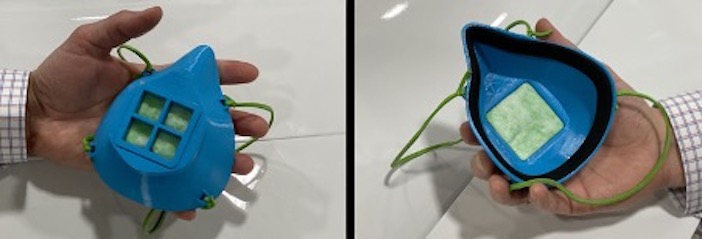

Tamarack’s engineers have been 3D printing reusable, protective respiratory masks based on a design developed by doctors in Billings, Montana named the Montana Mask. The masks include a small industrial filter which provides equivalent protection to the N95 mask.

Using in-house company resources like CAD and several 3D printers, Tamarack has so far produced more than 60 masks and the efforts will continue until the need subsides.

Tamarack’s president Jacob Klinginsmith said, “When we heard that our local hospital, Bonner County General Hospital, was running low on some vital protective gear, we tapped into our resources to see where we could help meet their needs.”

Meanwhile, others on the Tamarack team have been using their crafting skills to sew face masks to help meet the urgent need and employees have made over 50 masks. The sewn and 3D-printed masks are being distributed directly to Bonner County General Hospital.

“I am proud to be a part of a community where friends, neighbors, and businesses come together in times of need. We have a team of talented and generous people who are excited to take on this challenge,” said Tamarack’s chief Engineer, Nathan Cropper.

Tamarack also reached out to their connections in Shenzhen, China to help Bonner County General Hospital source 2,400 FDA approved N95 masks when the hospital’s normal supply chain was experiencing serious delays.

“Tamarack is helping in these small ways, but our hats are off to the front-line folks working tirelessly to treat, study, and contain the COVID-19 virus,” said Klinginsmith.

Tamarack encourages others interested in printing these or similar masks to visit the Billings firm’s website at www.makethemasks.com and to coordinate with their local hospitals.