Words by Andrew Rushton, aviation market manager, Conidia Bioscience

Covid-19 has rendered an extraordinary number of aircraft out of action as the demand for global travel plummeted. As the world starts to find its way back to a new normal, what challenges does this present to the aviation industry?

The number of aircrafts in storage or active parking conditions for long periods has presented an unusual level of risk relating to microbiological contamination of fuel. Although routines for storage and active parking are in place, returning to standard fuel testing frequencies at predetermined intervals may not be enough. As aircrafts return to the air, this unfamiliar transition period for such a quantity of planes should be approached with caution. Do the risks of contamination return to ‘normal’ levels immediately after return to service, or is there more likely to be a phased scaling down of risk?

What is microbiological contamination?

Microbiological contamination covers multiple types of organisms, including bacteria, mould and yeast, the presence of which will vary according to individual site conditions based on factors including temperature and humidity. The lead organism is most often Hormoconis resinae (H.res), which has a filamentous (long stranded) fungi structure. This acts as a binding material for other microorganisms to cling to which results in the formation of layers of biomass in the fuel. This biomass can block filters and fuel lines, adding to maintenance activities, costs, and risks to safety. Furthermore, these biomass layers generate organic acids that can cause pitting corrosion to the metal surfaces they touch, resulting in damage to fuel tanks and other ancillary equipment.

Why is the transition period to normal service a risky time for operators?

Operators are well-aware of the damage and cost associated with microbiological contamination, and that having aircrafts on the ground for long periods with small amounts of fuel lying dormant creates a much higher risk of contamination. During active parking, testing is typically carried out as frequently as every 14 days, as there is a much higher risk of contamination. But what happens when the aircraft returns to service? ‘Normal’ procedures will likely mean testing returns to yearly intervals. If active parking had been a relatively short period, this would be a sound strategy. However, high volumes of aircrafts have been parked or in storage for much longer this year, and this presents a possibility of new contamination scenarios due to the growth of contamination on tank walls and surfaces above the fuel.

In modern times we have not experienced the challenges faced during this pandemic. It is not surprising, therefore, there is no definitive guidance for fuel testing in this situation. Aircrafts in active parking condition are kept with 10-15% of fuel, and engines run on a weekly basis to help reduce the risk of problems. What may not have been considered, however, is that just testing a sample from the ~2,000 litres of fuel in the bottom of tanks for microbiological contamination may not give the full picture, indicating that the transition period back into full service could be a time for caution.

As the fuel has laid in the bottom of the tanks with little agitation, taking a fuel sample does not allow for the detection of microbiological growth on tank walls above the fuel line. As the aircrafts have been grounded for so long, moisture and condensation give microbes a breeding ground on tank walls. In these circumstances, just applying biocides may not be totally effective, as the biocide will only be within the fuel layer at the bottom of the tanks. When the tanks are fully refueled, actively growing contamination may be refreshed by fresh fuel stocks. Fuel from high pressure hoses may also dislodge patches of growth, which can then be dragged through engine fuel filters and auxiliary power unit (APU) filters, creating blockages.

Normal contamination in fuel tanks of aircrafts in full service takes months or years to develop, hence the longer testing frequencies (6-12 months on average, depending on risk) under normal conditions. The problem during this transition period, however, is the unseen residue of contamination that already exists inside the tanks. Microbe populations can fluctuate over time, but a residue could be lurking unnoticed for a period after return to service, especially as many aircrafts are only being utilised at around 50% of normal operations.

Testing recommendations as aircraft return to service

Of course, there are other steps operators can take to check fuel tanks for contamination, and additional mechanical and visual checks are recommended. However, it is not easy to see all aspects of the tanks, especially in the wings. As microbe residue may be present, it would be prudent, therefore, to increase the frequency of microbiological testing during the period after the aircraft returns to service. This more regular monitoring should be continued until there is more certainty that there is no microbiological ‘aftermath’ from active parking or storage.

The true cost of testing

Testing for microbiological contamination can stop unnecessary cleaning processes, reduce use of costly biocides, and lower maintenance overheads, giving a clear return on investment.

Furthermore, the cost of testing becomes almost completely insignificant should undetected contamination cause damage to fuel systems. If a wing tank needs to be defueled, further high costs and logistical issues come into play, as not all airports can provide this service or dispose of the contaminated fuel safely.

Fuel testing does not need to be expensive or time-consuming. Indeed, the quicker the tests can be carried out after a fuel sample is taken, the more accurate the results are likely to be as delays and changes to the environment may mean microbes die, and a false test result produced.

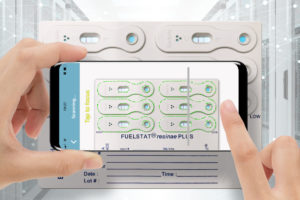

Immunoassay antibody test kits, applying medical grade technology to fuel testing can offer an onsite, economical alternative to laboratory testing. Now listed as an appropriate test method for many aircraft types, and recognized by international standards, test kits use antibodies that bind to a specific antigen to detect its presence and produce a measurable signal in response to this binding that can be used to assess fuel contamination levels.

The kits provide a clear ‘yes’ or ‘no’ as to whether the fuel is contaminated, along with indication of the level of contamination using a ‘traffic light’ system, giving the engineer the necessary data to decide whether biocide dosing or a complete fuel drain and tank clean is needed. No special training, handling, storage, or disposal (beyond the usual procedures for disposal of fuel) of the test kits is required. Having instant on-site results not only reduces costs and logistics of testing, but also avoids delays with many laboratories already overloaded with Covid-19 testing.

It has been a strange and challenging year for airline operators, creating exceptional logistical and economical challenges. As the industry looks to get more airlines back into much-needed service, this transition period should be approached with additional caution to allow for the unusual circumstances that aircraft and their fuel systems have been subjected to. Although the industry does not have definitive guidance for the current situation it finds itself in, it is suggested that maintaining a cautious approach to fuel testing frequency would be prudent at this time. Immunoassay test kits provide a fast, readily available, low-cost, accurate testing option, providing results in line with industry guidelines on acceptable levels of microbiological contamination.